Descriptions

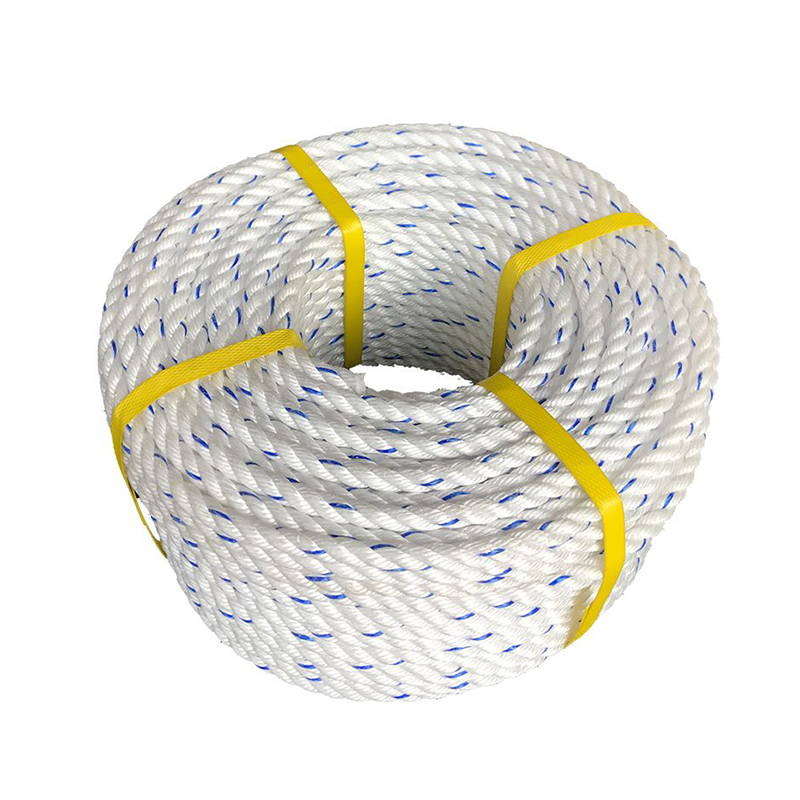

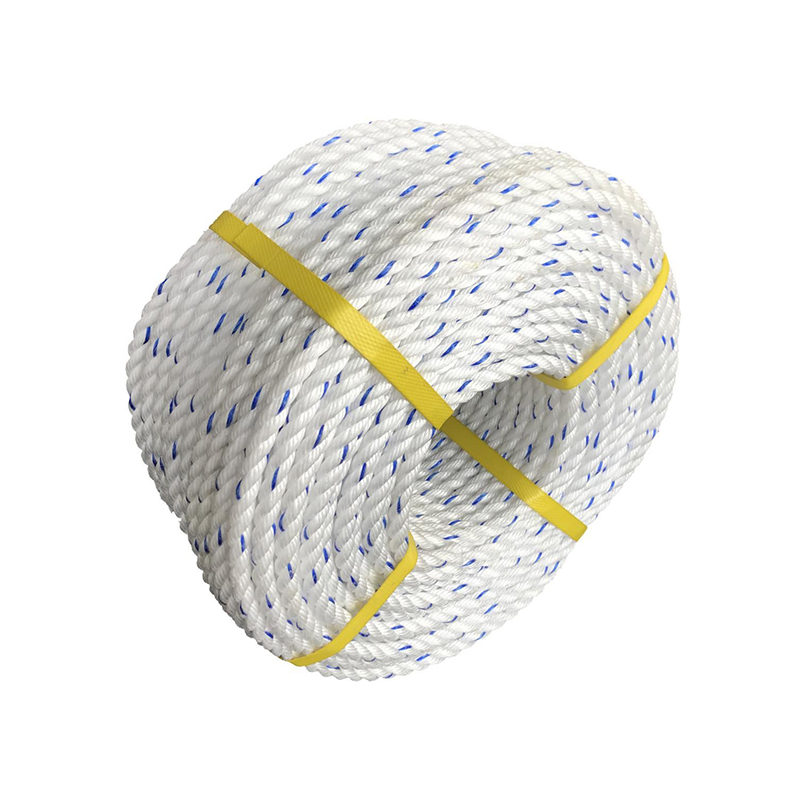

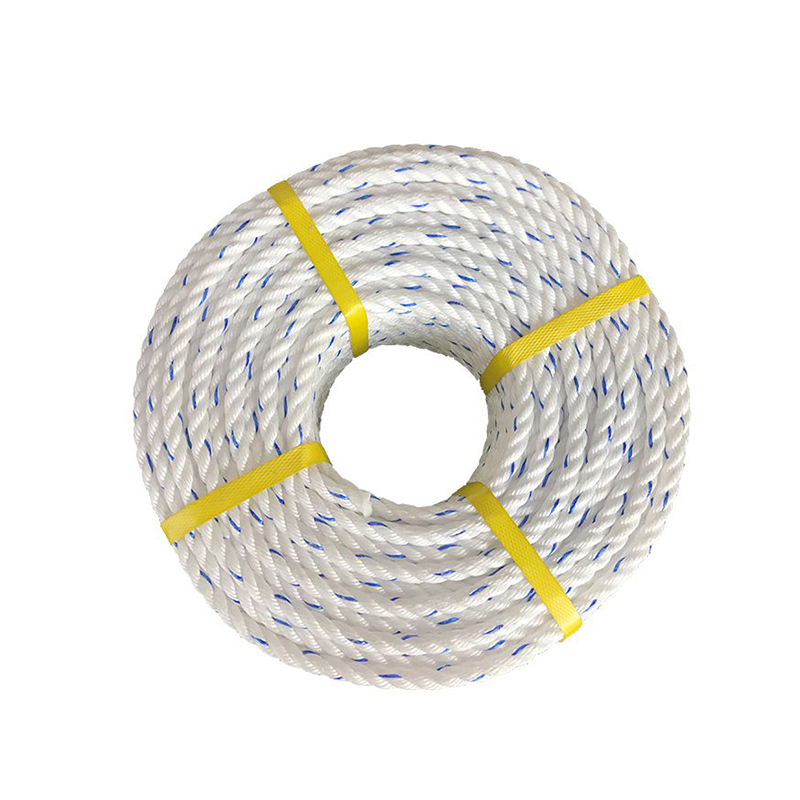

Polypropylene rope, also known as light rope or commercial rope, is a versatile type of rope commonly used in various applications. This is a great value rope perfect for a variety of uses due to these benefits:

Lightweight: Polypropylene rope is known for its light weight, which makes it easier to handle, transport, and store.

Floating: Polypropylene has a low density, allowing the rope to float on water. This characteristic makes it ideal for marine applications, such as boat lines or buoys.

High strength: Although polypropylene rope is lightweight, it still offers good strength and load-bearing capabilities. It is commonly used for securing, lifting, tying, and towing heavy objects.

Rot-proof: Polypropylene is rot-proof and resistant to moisture. It is completely immune to rotting, maintaining its strength and capability for much longer than other rope types.

Abrasion resistance: Polypropylene rope has good resistance to abrasion, reducing wear and tear during use. This characteristic makes it suitable for applications where the rope may come into contact with rough surfaces.

Cost-effective: Polypropylene rope is generally more affordable compared to other types of ropes. This makes it a popular choice for various commercial and industrial applications.

One issue with polypropylene to consider is that UV light slowly breaks down the fibers of the rope. Over time, if left outside, this rope will take on a rough and fuzzy appearance. This is perfectly normal, but makes the rope pretty scratchy.

PP rope is a general-purpose rope, suitable for various applications. It has a density of 0.91 meaning this is a floating rope. This can be beneficial in certain applications, such as marine or water-related activities.Our PP danline rope is manufactured by mono-filament, also called danline fiber. It comes in a 3 and 4 strand construction with a variety of colours. We can make the soft lay, medium lay, hard lay and super hard lay. The melting point of polypropylene is 165°C.

Each piece of our rope has no splices. It is wise not to have any splices in the rope because splices introduce weak points in the rope where it could potentially fail under pressure or during use. Furthermore, the absence of splices also makes the application of the rope more convenient. Without splices, the rope can be more easily handled, knotted, and secured. It provides a smoother and uninterrupted surface, enabling efficient use of the rope in various applications.

In summary, not having any splices in your rope is a smart choice as it helps maintain its strength and increases convenience during usage.

The tensile strength of a rope refers to its maximum load capacity before it breaks. This number is the amount of weight that the rope should be able to hold in ideal conditions, specifically, a new rope, with no knots or splices, at room temperature.

We test our ropes personally, and all our QA inspectors have their work tested on an ongoing basis using a certified test bed facility. This is to ensure that the test result is in a controlled and scientific manner, leading to reliable and accurate test results. This helps in maintaining the quality and consistency of the products, which ultimately benefits the customers and the reputation of the company.

Rope wear, knots, extreme hot or cold temperatures, chemicals, the manner in which the load is applied and other factors will result in a break strength lower than the stated average break strength.

A rope with a stated or advertised break strength, in kilograms will not necessarily safely hold something that weighs that amount!

In a broad generalization, most working loads vary from 1/10 to 1/4 of the average break strength of the rope. Applications for rope used in life support or personal fall protection environments must use the 1/10 ratio.

we provide quality-certified PP ropes at an affordable price, and also provide PE rope and Twine, PP Baler Twine and PP Raffia, Polysteel Rope, Braided Rope,Tiger Rope, Lead Core Rope, Mooring Rope, Nylon Fishing Line, Fishing Twine, etc. Our ropes are widely appreciated by customers for their high durability, best quality and longer lifespan.

Applications of PP Ropes

Marine: marine anchor rope, guide rope, sling, whiplash, lifeline, Boating, pulleys and winches,cargo net, etc.

Fisheries: Anchor ropes, floating ropes, fishing rope,trawler fishing, tow ropes for cultured pearls and oysters, etc.

Techinical Sheet

| SIZE | PP Rope(ISO 2307-2010) | |||||

| Dia | Dia | Cir | WEIGHT | MBL | ||

| (mm) | (inch) | (inch) | (kgs/220m) | (lbs/1200ft) | (kgs or tons) | (kn) |

| 4 | 5/32 | 1/2 | 1.32 | 4.84 | 215 | 2.11 |

| 5 | 3/16 | 5/8 | 2.45 | 8.99 | 320 | 3.14 |

| 6 | 7/32 | 3/4 | 3.75 | 13.76 | 600 | 5.88 |

| 7 | 1/4 | 7/8 | 5.1 | 18.71 | 750 | 7.35 |

| 8 | 5/16 | 1 | 6.6 | 24.21 | 1,060 | 10.39 |

| 9 | 11/32 | 1-1/8 | 8.1 | 29.71 | 1,190 | 11.66 |

| 10 | 3/8 | 1-1/4 | 9.9 | 36.32 | 1,560 | 15.29 |

| 12 | 1/2 | 1-1/2 | 14.3 | 52.46 | 2,210 | 21.66 |

| 14 | 9/16 | 1-3/4 | 20 | 73.37 | 3,050 | 29.89 |

| 16 | 5/8 | 2 | 25.3 | 92.81 | 3.78Ts | 37.04 |

| 18 | 3/4 | 2-1/4 | 32.5 | 119.22 | 4.82 | 47.23 |

| 20 | 13/16 | 2-1/2 | 40 | 146.74 | 5.8 | 56.84 |

| 22 | 7/8 | 2-3/4 | 48.4 | 177.55 | 6.96 | 68.21 |

| 24 | 1 | 3 | 57 | 209.1 | 8.13 | 79.67 |

| 26 | 1-1/16 | 3-1/4 | 67 | 245.79 | 9.41 | 92.21 |

| 28 | 1-1/8 | 3-1/2 | 78 | 286.14 | 10.7 | 104.86 |

| 30 | 1-1/4 | 3-3/4 | 89 | 326.49 | 12.22 | 119.75 |

| 32 | 1-5/16 | 4 | 101 | 370.51 | 13.5 | 132.3 |

| Brand | Dongtalent |

| Color | Color or customized |

| MOQ | 500 KG |

| OEM or ODM | Yes |

| Sample | Supply |

| Port | Qingdao/Shanghai or any other ports in China |

| Payment Terms | TT 30% in advance, 70% before shipment; |

| Delivery Time | 15-30 days upon receiving the payment |

| Packaging | Coils, bundles, reels, carton, or as you need |